In the modern packaging world, printing quality is one of the most important factors for product success. When a customer picks a product from a shelf, the first thing they see is the packaging design, colors, and overall finish. This is where a Rotogravure Printing Machine becomes very important. It is known for producing high-quality, sharp, and professional prints on packaging materials.

In Dubai, UAE, and the Middle East, packaging standards are very high. Many industries, such as food, pharmaceuticals, and FMCG, need strong, attractive, and export-quality packaging. A Rotogravure Printing Machine helps companies meet these expectations easily.

What Is a Rotogravure Printing Machine?

A Rotogravure Printing Machine is a printing machine mainly used for packaging materials. It prints images, brand logos, product information, and designs on materials like plastic films, paper, aluminum foil, and laminated sheets. This machine is specially designed for large-scale printing where the same design needs to be printed again and again.

One of the biggest reasons companies prefer rotogravure printing is its consistency. Even after long production hours, the print quality remains the same. In Dubai and the UAE markets, where branding and presentation are very important, rotogravure printing is widely used for premium packaging solutions.

How Does the Rotogravure Printing Process Work?

The rotogravure printing process is easy to understand when explained in simple words. In this process, the design is first engraved on a metal cylinder. This cylinder has thousands of very small engraved cells that hold ink.

During printing, the cylinder rotates in an ink tray where ink fills these tiny cells. Extra ink on the surface is removed with a blade, leaving only the required ink inside the cells. When the packaging material passes over the cylinder, pressure transfers the ink from the cells onto the material. After printing, the material is passed through a drying system to remove moisture and ensure the ink is properly fixed.

This process is repeated for each color, which helps create bright, clean, and sharp prints suitable for high-end packaging.

Materials That Can Be Printed Using a Rotogravure Printing Machine

One major reason behind the popularity of the Rotogravure Printing Machine is its ability to print on a wide range of materials. This flexibility makes it perfect for different types of packaging industries.

Plastic Films (BOPP, PET, CPP, LDPE, HDPE)

Rotogravure printing works extremely well on plastic films used in flexible packaging. Materials like BOPP, PET, CPP, LDPE, and HDPE are commonly printed using this machine. These films are widely used for food packets, snack pouches, shopping bags, and wrapping materials. The machine provides strong ink bonding and smooth color finish on plastic surfaces.

Paper and Paperboard

Paper and paperboard are still very important packaging materials, especially for boxes, wrappers, and outer covers. A Rotogravure Printing Machine prints clearly on paper-based materials, producing sharp text and clean images. This makes it suitable for both simple and premium paper packaging used in the UAE market.

Aluminum Foil

Aluminum foil is commonly used in food and pharmaceutical packaging because of its barrier properties. Rotogravure printing provides excellent ink adhesion on foil surfaces. The prints remain clear and readable even after long storage, making it a reliable option for sensitive products.

Laminated Packaging Material

Modern packaging often uses laminated materials with multiple layers for strength and protection. Rotogravure Printing Machines handle laminated materials very efficiently. They produce high-quality prints without damaging the layers, making them ideal for premium and export-quality packaging.

Applications of the Rotogravure Printing Machine

The Rotogravure Printing Machine is used in many industries because of its reliability and print quality. It supports both local and international packaging needs.

Food Packaging

In food packaging, safety and appearance are equally important. Rotogravure printing is widely used for chips, biscuits, chocolates, spices, frozen food, and dry food packaging. The machine ensures clear product information and attractive designs that increase shelf appeal.

Pharmaceutical Packaging

Pharmaceutical packaging requires high print accuracy for dosage instructions and safety details. Rotogravure printing delivers sharp and readable text, making it suitable for medicine sachets, strips, and outer packaging used in hospitals and medical stores.

FMCG Products

Fast-moving consumer goods like shampoo sachets, detergent packs, soap wrappers, and household products need eye-catching designs. Rotogravure printing helps brands maintain a strong identity with consistent colors and professional printing.

Labels, Pouches, and Flexible Packaging

Rotogravure printing is also used for labels, stand-up pouches, zipper pouches, and roll stock used in automatic packing machines. Its flexibility makes it a preferred choice for modern packaging formats.

Key Benefits of a Rotogravure Printing Machine

A Rotogravure Printing Machine offers many advantages that make it a long-term investment for packaging businesses.

High-Quality and Sharp Printing

This machine produces very sharp images, smooth color tones, and fine design details. The print quality looks premium and helps brands stand out in competitive markets like Dubai.

Long Print Cylinder Life

The engraved cylinders used in rotogravure printing have a very long life. They can produce millions of impressions without losing quality, which reduces replacement costs over time.

High-Speed Production

Rotogravure machines are designed for high-speed printing. This helps manufacturers complete large orders quickly and meet tight delivery deadlines.

Consistent Print Quality

One of the biggest strengths of this machine is consistency. From the first roll to the last roll, the print quality remains uniform, which is very important for brand trust.

Ideal for Bulk and Export-Quality Packaging

Because of its speed and quality, rotogravure printing is perfect for bulk production and packaging meant for export markets.

Types of Rotogravure Printing Machines

Different types of Rotogravure Printing Machines are available to match different production needs.

Shafted Rotogravure Printing Machine

A Shafted Rotogravure Printing Machine uses mechanical shafts to mount the printing cylinders. It is strong, stable, and suitable for long production runs. Many traditional packaging units still use this type because of its durability.

Shaftless Rotogravure Printing Machine

A Shaftless Rotogravure Printing Machine is more advanced and flexible. It allows faster cylinder changes and better control, making it suitable for modern and high-efficiency packaging plants.

Multicolour Rotogravure Printing Machine

A Multicolour Rotogravure Printing Machine can print multiple colors in a single run. This is very useful for colorful and attractive packaging designs required in the FMCG and food industries.

Alternative and Related Printing Machines

Apart from rotogravure printing, other machines are also used in the packaging industry, depending on requirements.

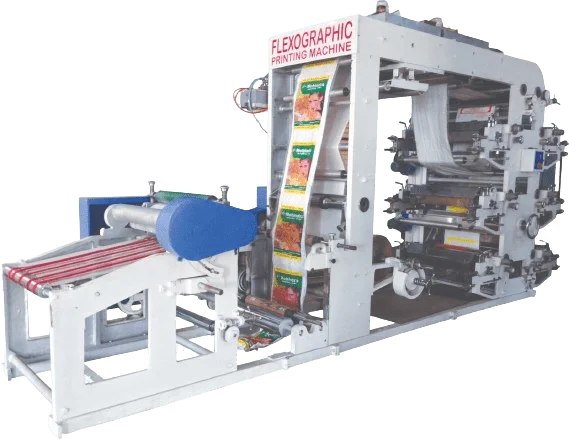

A Foil Printing Machine is mainly used for aluminum foil and metallic packaging. A Flexo Printing Machine is suitable for short and medium runs and offers lower setup costs. A CI Flexo Printing Machine provides better consistency for flexible packaging, but still cannot match rotogravure quality for premium designs. A Label Printing Machine is mainly limited to sticker and label production.

Among all these options, a Rotogravure Printing Machine remains one of the most reliable packaging printing machine choices for large-scale and export-oriented businesses.

Why the Rotogravure Printing Machine Is Best for Dubai & UAE

Dubai and the UAE are major hubs for food processing, FMCG manufacturing, and exports. Packaging quality here must meet international standards. A Rotogravure Printing Machine supports large production volumes, premium designs, and consistent quality.

Because of the strong demand for attractive and durable packaging, many UAE manufacturers prefer rotogravure printing. It helps them compete in global markets and build strong brand value.

Final Thoughts

A Rotogravure Printing Machine is a powerful and reliable solution for the packaging industry. It offers excellent print quality, high-speed production, and long-term cost benefits. Whether you are printing on plastic films, paper, aluminum foil, or laminated materials, this machine delivers professional results every time.

For packaging businesses in Dubai, UAE, and the Middle East, investing in a Rotogravure Printing Machine is a smart decision for growth, exports, and premium packaging success.